Solutions

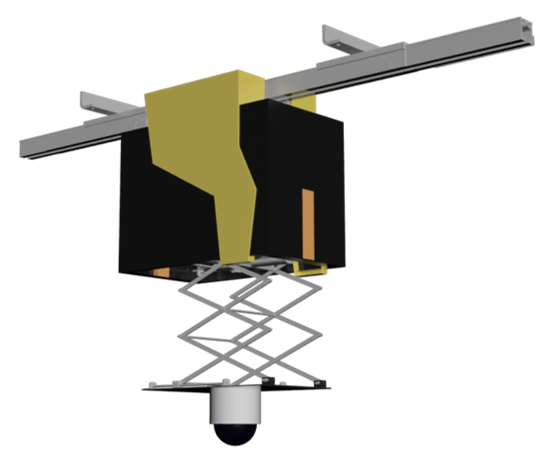

Multi-modal Inspection Robot Solution

When we need to conduct inspections in various types of workplaces, different forms of inspection robots, such as wheeled, orbital robots or drones, can be used in specific workplaces to reach any designated location. Carry out survey and maintenance operations.

Outdoor

Inspection Robot

Indoor Orbital

Inspection Robot

Hindrance

Cleaning Drone

Inspection robots are suitable for areas with dense equipment, such as substations, chemical plants, semiconductor factories, data centers, etc. By carrying different sensors, surveys can be carried out with designated instruments. For example: use thermal imaging cameras to detect power generation, batteries, motors and other equipment to see if there is a risk of overheating; use gas detectors in semiconductor factories and chemical plants to detect whether toxic substances leak accidents; use high-magnification cameras Interpret various digital analog instruments; judge whether there is an abnormality in the instrument by acoustically collecting the noise at each frequency of the equipment; or use a high-payload drone to clean high-altitude insulation barriers, etc.

Taiwan Intelligent Robot Technology is involved in various types of robots in the industry, using positioning and navigation technologies such as 3D SLAM and landmark. Robots suitable for inspections in each specific field can be quickly integrated, and combined with sensing equipment adapted to the environment of each work site, to achieve the purpose of inspection and maintenance.

By introducing and applying diverse inspection robots, the deployment of relevant inspection personnel can be reduced and the frequency of inspections can be increased. Especially in dangerous areas that are difficult for inspection personnel to enter, the benefits of robots can be better utilized to achieve specific results of saving manpower and improving industrial safety.

Personnel and equipment inspection solutions covering multiple payloads including optical/acoustic/gas

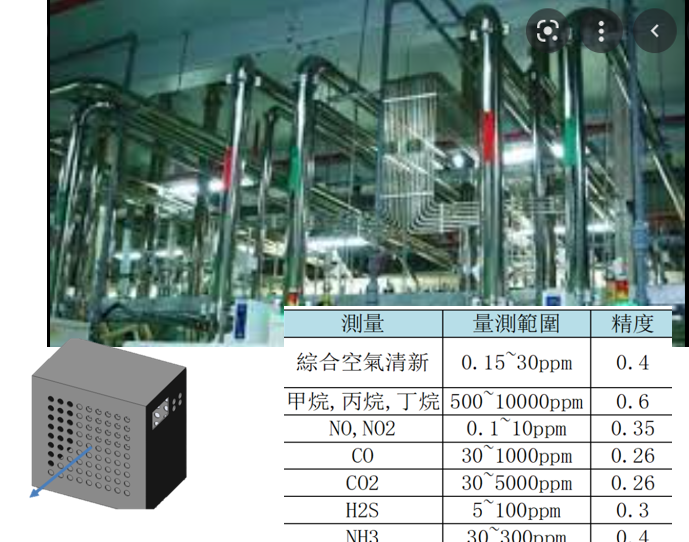

Environmental gas monitoring

Integrated gas sensors monitor environmental conditions

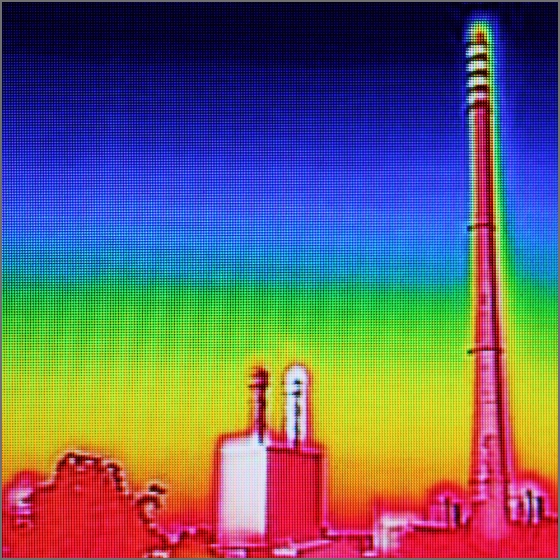

Environmental thermal imaging temperature detection

Thermal imaging camera detects abnormal temperature of objects

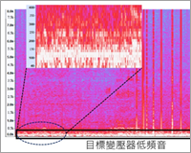

Instrument abnormal sound detection

Acoustic component testing instrument operating status

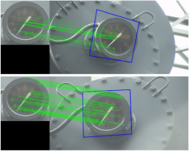

Visible light image reading

Using AI to identify images

Industrial Safety Identification: Object Class

Qualified shooting screen detection

Safety clothing wearing detection

Equipment abnormal status detection, etc.

Industrial safety identification: incident type

Abnormal disaster detection

Detection of abnormal personnel behavior

Construction equipment operation safety detection

Detection of industrial safety violations

Industrial Safety Identification: Rules

Construction situation detection

Judgment of behavior that complies with operating standards, etc.

MULTI-MODAL