OVERVIEW

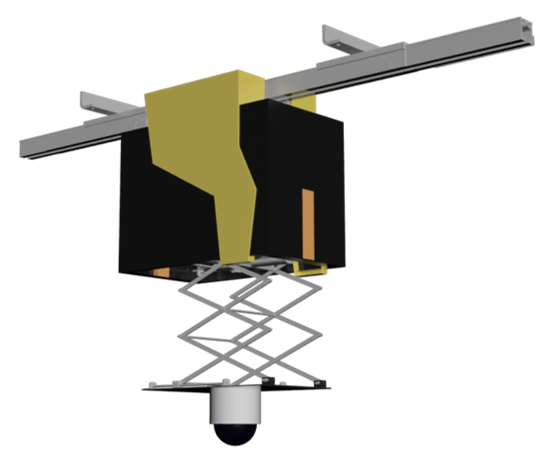

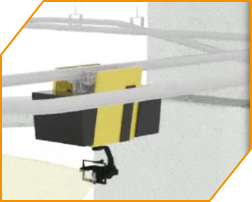

Indoor Orbital Inspection Robot

The Indoor Orbital Inspection Robot operates on a lithium iron battery, offering high safety. It can run for three to four hours on a one-hour charge, depending on the payload and application scenario. The robot can navigate slopes (up to 10°) and make small-angle turns (minimum radius: 30 cm) according to the terrain, allowing for all-terrain operation. Additionally, it is equipped with a safety brake that locks the robot in place during a power outage, preventing it from sliding. The track is made of acid and alkali-resistant, corrosion-resistant 6063 aluminum alloy. The specialized track and suspension design make installation and securing easier.

Track

- Ultrasonic

- Noise detection

- Gas detection

- Temperature and humidity sensor

Lifting arm

- Thermal imaging camera

- Visual camera

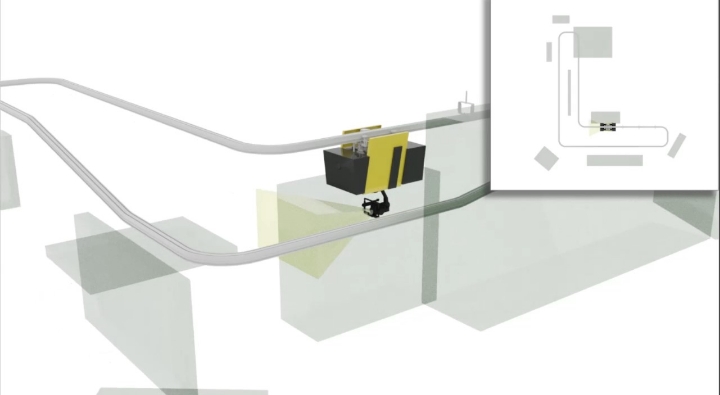

In terms of application, the Indoor Orbital Inspection Robot can have its sensors, payloads, and lifting modules adjusted according to the needs of the application environment. The lifting mechanism allows sensors to be lowered to the required height to perform relevant inspection tasks. In the application environment, personnel and robots are separated by height, operating in different spaces, which helps avoid safety risks. The system can be applied to corridors and indoor substations, semiconductor/panel plant facilities, utility tunnels, petrochemical and chemical plants, shared pipelines, data centers, and energy storage facilities. It brings significant value to the automation and intelligent operation and maintenance of power tunnels and underground tunnels, further enhancing operational safety and efficiency.

VIDEO

Scenario simulation animation

INSPECTION